EZ Strip

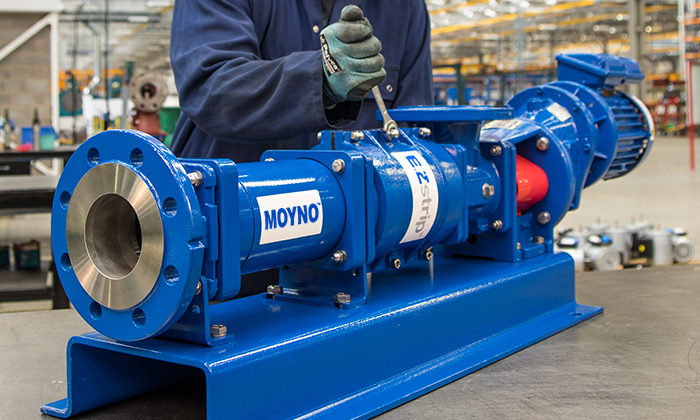

EZstrip™ Transfer Pump

The EZstrip™ Transfer Pump provides a quick and easy way to disassemble, de-rag, and maintain a PC pump in place, reducing maintenance time by more than 93% for significant cost savings. Distinguished by a patented split coupling, the EZstrip™ Transfer Pump offers direct access to the worn parts and rotating assemblies without affecting the operational parameters.

Features

- Patented split coupling allows full removal of the drive train in minutes with no electrical disconnection required

- Pre-assembled drive train available with a 2-year warranty to allow faster reassembly time

- Suction and discharge ports remain connected to the pipe work

- Operational parameters are unaffected since the design does not affect flow and pressure

- Low running speeds reduce wear for a longer working pump life; which ideal for abrasive applications

- Stainless steel cast components and fasteners provide corrosion resistance making them suitable for a variety of applications

Typical Applications

- Domestic and industrial effluent

- Hydrated lime slurry

- Sludge

- Shear-sensitive latex emulsion

- Milk curds, sauces, fruit juices

- Industrial chemicals and detergents

- Starch slurries

- Coating clays, gypsum, and silicate

- Paper stocks

- Agricultural slurries

EZstrip™ TR Muncher

CT201 A new addition to the EZstrip™ family of products, the CT201 TR Muncher® has been designed specifically to meet on-site tanker discharge requirements and sludge/fat processing, for maceration of solids within the flow and protection of downstream equipment from blockages.

Installation of the EZstrip™ CT201 TR Muncher® is simple, with in-line flanges or the option of tanker coupling connections. Quick-release inspection covers also allow in-situ replacement of the cutters, which can be specified to either 8.0mm, 5.5mm, or 3.0mm thickness, to match the optimum particle size for specific process requirements.

Features & Benefits

- Quick release access port allows the cutter assembly to be maintained in place without removing the equipment and therefore reduces maintenance time.

- Rotational speed produces high torque, resulting in lower operating power at 1.5 or 2.2kW, which are available with energy-efficient motors.

- Lower cutter tip speeds dramatically reduce wear rates. Slow speeds also ensure low noise and vibration, and good abrasion resistance.

- Off-loading requirements for ‘on-stand’ tankering are matched by the Muncher’s capacity.

- The pull-back cutter stack allows removal without disturbing the pipeline.

CT203 & CT205

Designed specifically for the efficient maceration of abrasive sludges, the EZstrip™ CT203/05 TR Munchers are very effective in capturing irregularly shaped objects. The layback cutter shafts on this Muncher are set at an angle to the incoming flow. If a rejection cycle is necessary, the object can drop into the built-in trash trap set clear of and below the cutter stacks, preventing damage. The trash trap is fitted with a large diameter access port to enable easy removal, cleaning, and flushing.

Features & Benefits

- Moyno ETOS cutters offer positive and effective solids maceration

- Shafts operate at differential speeds to promote a tearing action on the solids

- The pull-back cutter stack allows removal without disturbing the pipeline

- Cantilever shaft design eliminates the need for bottom bearings and seals, significantly reducing wearing components

- Patented built-in trash trap with clean-out ports to catch any rejected material

- Low cutter tip speeds, low power and low noise level

- Each Muncher is supplied with a programmable logic controller (PLC) to protect the machine against damage and overloads

- Munchers can be supplied to comply with the ATEX Directive 94/9/EC