Grundfos Centrifugal Pumps

Grundfos Vertical Multistage

The basic CR pump range, which can be applied in almost any industrial solution, is already in itself the broadest range available.

Grundfos Dosing

Grundfos offers a wide range of dosing pumps representing state-of-the-art technology. Digital Dosing solutions (SMART Digital, DME, DDI) set new standards in liquid chemical handling and accuracy.

Grundfos Submersible Pumps

Grundfos SP submersible pumps are renowned for their high efficiency and reliability throughout the range. Made entirely of corrosion-resistant stainless steel, SP pumps are ideal for a wide variety of applications.

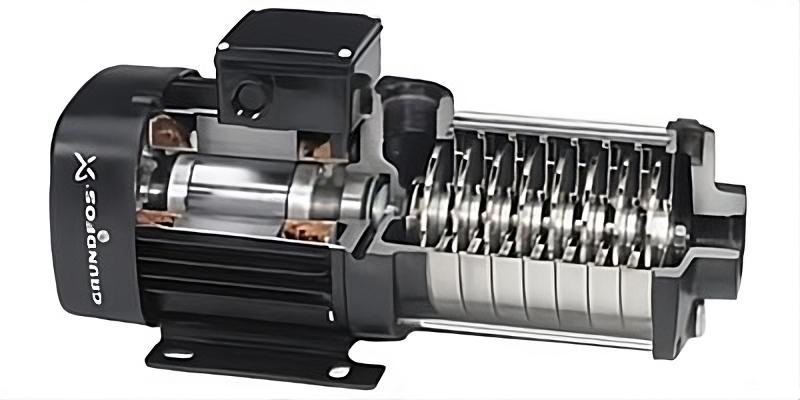

Grundfos Horizontal Multistage CM

The horizontal multistage pump CM (Centrifugal Modular) has been created with compactness and modularity as two of its central features, making numerous configurations possible.

Grundfos Vertical Immersible

MTR, SPK, CRK, MTC, and MTA pumps are vertical multistage centrifugal pumps designed for the pumping of cooling lubricants for machine tools, condensate transfer, and similar applications.