Moyno 2000

2000 pumps set the standard in positive displacement pumping applications. The proprietary 2000 gear-type universal joint design effectively handles radial and thrust loads for maximum performance and long life.

These rugged pumps can handle abrasive materials over 80% solids and offer a performance range of 4,500 GPM with a pressure of 1,500 PSI.

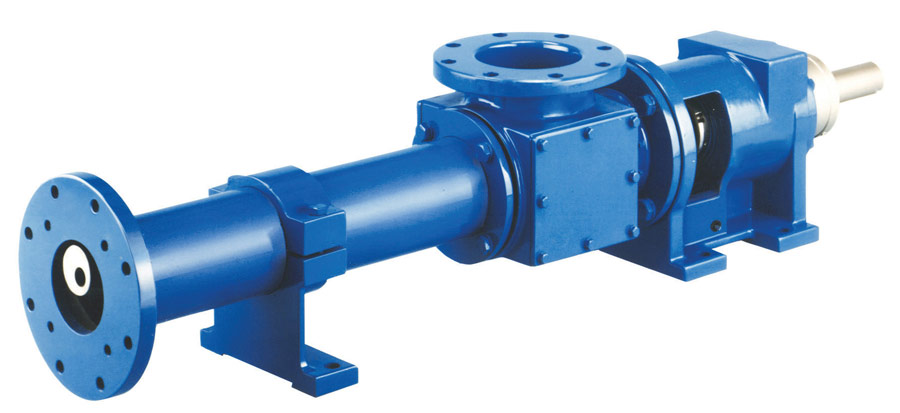

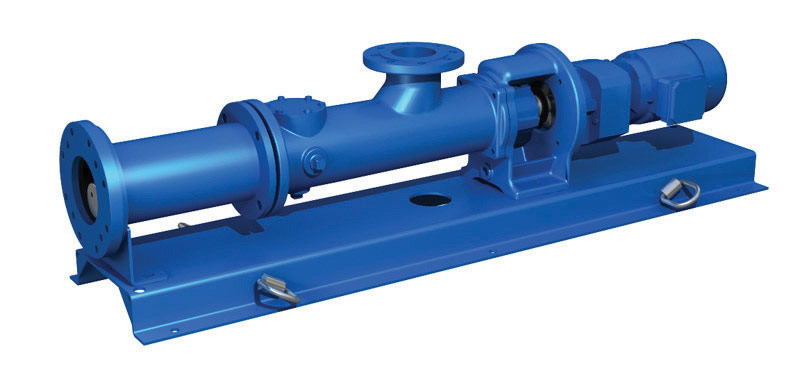

G1 – Flanged Design

Versatile, high-performance pump designed to handle a wide range of applications from shear-sensitive chemicals to difficult-to-process slurries and sludges. Due to their rugged design, these pumps offer low maintenance, minimal downtime, and long service life for a low total cost of ownership. They utilize heavy-duty gear joints and bearings to handle the most difficult applications. The hollow drive shaft design results in a compact pump that significantly extends bearing and seal life.

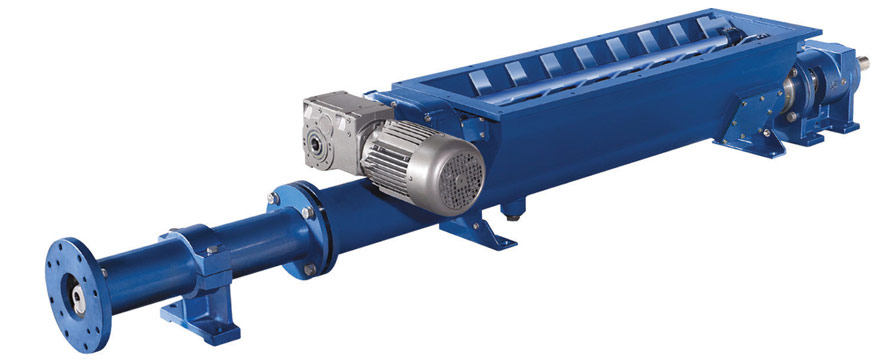

G2 – Single Auger Feed

Versatile, high-performance pump featuring a wide, open throat hopper design that minimizes plugging that could occur in a standard inlet.

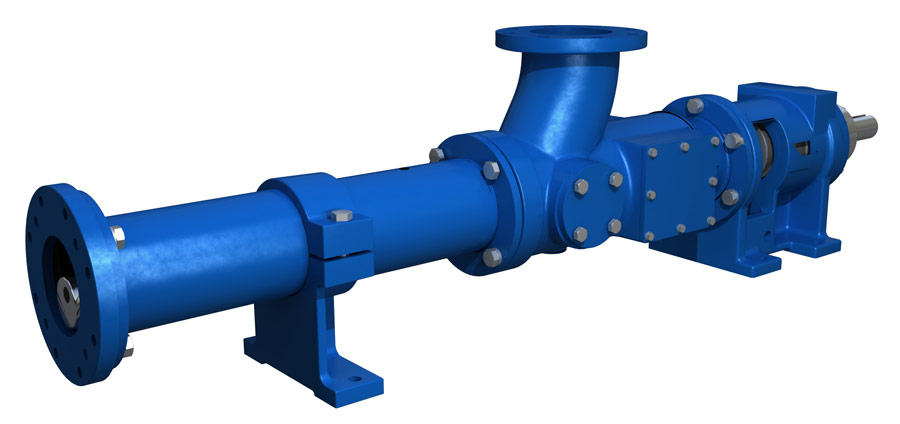

G3 – Bridge Breaker

Suited for handling semi-dry, high solids content fluids that tend to “bridge” in the inlet hopper.

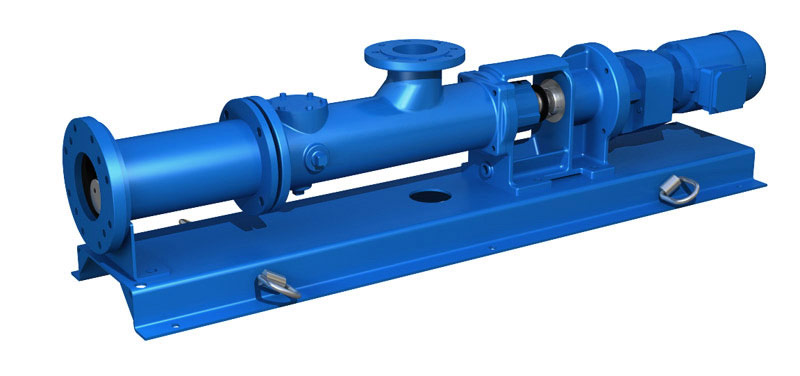

G4 – 45-degree Inlet Design

45-degree inlet lowers friction loss and provides for gentler handling of the product.

2000WA

Close Coupled DesignThe 2000WA close-coupled pump is specifically designed for lower pressure, lower flow applications that do not require the full features and benefits of the 2000G1 pump. The 2000WA features a close-coupled design that has integral bearings that support the radial thrust loads that can be seen at the rotor/stator. This design reduces the overall stress that can occur in the gear reducer on standard close-coupled designs. It is specifically designed for applications that require the transfer of highly viscous fluids and solids where a close coupled configuration is preferred, but the robustness of a gear joint is desired.

2000WB

Traditional Close-Coupled Design close-coupled pump is specifically designed for applications that require the transfer of highly viscous fluids and solids where a close-coupled configuration is preferred, but the robustness of a gear joint is desired.